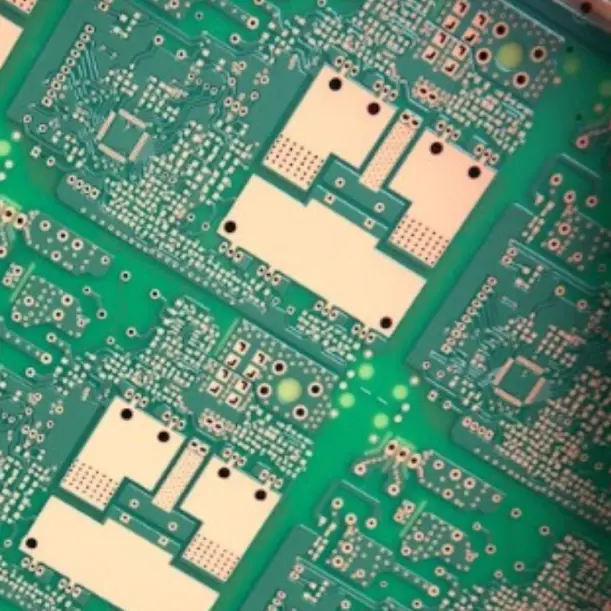

Double-Sided PCBs

At Epitome, with a unit dedicated to manufacturing double-sided PCBs, we exemplify quality, production standards and customer-centricity. Here’s more to our double-sided PCBs and its benefits.

- Robust and reliable manufacturing process.

- Same bath used to etch both sides at the same time.

- Increased surface area in the same-size-single-layer board due to the second layer of copper and vias in a double-layer board.

Details of Our Double-Sided PCBs

Here are technical features of our double-sided PCBs.

-

Type of Laminates Used

FR4, High TG FR 4, PTFE, CEM3

-

Laminate Thickness

0.4 mm to 3.2 mm

-

Base Cu Foil Thickness

18/18, 35/35, 70/70, and 105/105 µm

-

Min. Track Width/Space

4/4 Mil

-

Min. Drill Size

0.2 mm

-

Maximum PCB Size

1200mm X 630mm

-

Surface Finish

OSP, HAL (Lead Free/ Tin Lead) Immersion Tin, Electrolytic Gold Plating, ENIG

-

Other Capabilities

Carbon Key, Peelable, Via Filling, Blind and Buried Vias

Production Infrastructure Used in Double-Sided PCBs

At Epitome, we leverage the latest and the most competent infrastructure to maintain the expected and world-class quality standards for our clients, each of which is a brand.

- CNC drilling – 100 spindle capacity

- Horizontal De-Smear and direct metallization line

- Class 10K Clean Room for Photo Imaging

- Cut sheet laminator

- CCD camera assignment exposing machine

- Vertical Continuous Plater (VCP) Lines

- Vacuum etching line

- Automatic Optical Inspection (AOI), SES, DES

- Fully automatic screen printing for photo image able solder mask, class 100K clean room

- Fully automatic legend printing

- HAL (TIN lead), HAL (lead free), horizontal immersion TIN, OSP, ENIG lines , Electrolytic Gold Plating.

- Auto BBT, Universal BBT, Flying Probe Testers

- Plasma Desmear for PTFE laminates.